Al, thanks... as I reflect with detail on the sound I hear when backing out of the driveway over the gutter while turning hard to or near the stops, you're absolutely right.

I spent more time today trying to isolate where the sound "click" I hear when lifting or push/pulling up/down on the spindle. While I cleaned joints off even more and spent effort to see if I could actually see any motion, I still can't see anything, so it's hidden inside something.

However, I was able to isolate where the sound is emminating from... at least approximately, and have eliminted some possibilities at the very least.

The sound is coming from above the upper control arm or at the upper shock mounting area. I listened carefully following the sound and believe its under the shock cover (new bilstein shocks, properly installed with an MB W113 professional expert by my side while I did the work). That's not the final word, but the intermediate analysis thus far is that it's a click in the unloaded shocks.

I can say with certainty though that it isn't coming from either control arm bushings, either inner or outers, upper or lower, nor the trailing arm or anything in that area --- spelled RELIEF! Sound get's louder the closer I place my ear to the upper part of the fender well. I 'think' I feel something when I place my finger on the rod sticking up thru the upper mounting for the shock in the engine compartment... but that may be wishful thinking rather than objective, or I may be feeling a transmission of vibration by whatever's hitting whatever and creating the little "click" sound, rather than movement itself. I've placed my hand on suspension carrier that's attached a the upper part of the chassis, with the big rubber mount and can't feel anything there when I create the "click".... but these are the only two are's where anything comes from the spindle to the upper part of the wheel well.

I'll have to isolate it further and with certainty by attaching a dial indicator to things to see movement when I hear "click". I'll post more when I know more.

Upate Apr 4, evening:

I think I may have figured out where the "click" sound is... won't be able to see it and am still not absolutely sure, but from apparent sound source and design at top of the shock it fits what I've found thus far without any actual displacement measurements.

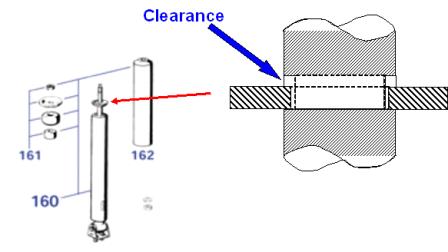

There's a captured retainer ring on the shock shaft at the top. Whether it's captured by wings on the shaft or indents (as shown in my diagram) is immaterial. There's a vertical clearance between the retainer thickness and the shaft's indent height or (wing opening height) in which the captured retainer sits. It is this clearance

that gives rise to the "click" sound as the shaft moves up when I pull up on the spindle (or any other part of the control arms / spindle asm)... and the captured retainer hits the other side

of the slot it's retained in (or protruding flags that retain it).

I admittedly haven't yet worked out why the forces are such that my pulling up on the spindle/control arms causes the click going "up", and again when I release my "up" force or pull down, but the gas filled shock shaft pushes up in it's normal state. When the wheel is suspended, the coil spring is pushing down on the lower control arm down to it's fullest extent, and therefore trying to pull the shock shaft down with it also.... though I distinctly recall that the force on the shock shaft was still pushing it "up" (since it was still difficult to compress the shock to get the two bolt studs at the bottom of the shock into the holes in the lower control arm), so the forces should still be forcing the shock shaft "up" even with the wheel fully suspended.

Longtooth

67 250SL US #113-043-10-002163

'02 SL500 Sport