Hi all

I received my FIP back last week. It was just calibrated and not a major rebuild. The tech opened it up and immediately saw the problem. The stylus was resting on the cam too far in the rich position. This explains the problem I was having. Some one must have been in there and calibrated it incorrectly years ago. From there, he just re calibrated everything to spec and checked the injectors and I sent up. I am now able to make adjustments to the pump and see desired results. Before it was so rich there was nothing I could do.

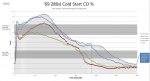

For the last several days I have been conducting cold start tests to further tune the pump and get everything running properly. I have documented the CO cold start curve using a Gunson and Iphone. See the attached chart for my first 4 tests. I still have some more tweaking to do but I feel confident that I will be happy with the results when done.

I logged the Gunson data by placing a iphone in front of the Gunson display and had it take a picture of the LED every 3 seconds. I ran the each test for 6 minutes except for TEST #4 which was for 15 minutes. From there I just entered data from the iphone pics (360 each test) into the excel file with the chart.

I have attached the excel file with chart so anybody can use it and track their own cold start.

Feel free to PM me if you don't know how to use the excel file. It's easy!

I'm still looking for other people with Gunson's to run this test so we can compare notes!Overall notes:

It seems the idle mixture screw on the FIP can but NOT necessarily affect the cold start up mixture. I assume this is because the FIP enriches the mixture so much at cold start that it might not have any affect. This real depends on how well your pump is calibrated.

Through my observations, a CO% somewhere in the area of 7.5% and 9.5% is the desired max CO to achieve a 1100 -1200rpm for a cold start.

The WRD air slide closes AFTER the the WRD heat feeler pin hits it's stop in the FIP. For my FIP this is making the CO dip to 1.5 - 2.0%. I would like more data from other FIP's to confirm that this CO range is normal. I believe it is normal but not sure by how much. My theory is that engine designers wanted the FIP to go a lean for a bit to clean off any carbon on the spark plugs during the enriched cold start. Like I said. Just a theory

Cold Start TEST Notes

Test #1 (10am)

Tested as it came back from FIP tech. Needed to find baseline to start adjustments of Air mixture & Idle mixture screw.

Test #2 (11am)

Adjusted air mixture screw CCW by 5 clicks. Set Warm CO to 3.8% at end of TEST #2 by 5 CW (enrich) clicks from calibrated default.

Test #3 (5pm)

CO still ended back in the 1.5% range even after setting it to 3.8% in TEST#2. I now believe it takes over 15 minutes to fully warm up by just idling. The CO curve is a little flat at beginning possibly do to the fact that the car was not 100% cold after 5 hours. WRD was slightly warm to touch. After taking car out the CO was back at 2.2%. Added 2 more clicks CW to enrich to 4.0% for Test #4

Test #4 (10am)

1100rpm was not achieved until after 2mins due to the fact that it was too rich. After 15 minutes, 3.0% CO and after long drive 4.0+%. I will probably dial down on click (CCW/lean) for next test.

For the sake of easy explanation I define a Air Mixture Screw "click" as one clock position (ex. 1 o'clock, 2 o'clock). Obviously, since it's a screw you have much more fine tuning.

Excel File

http://dl.dropbox.com/u/10334978/Mercedes%20280SL/Gunson%20CO%20Chart%20280SL%20%201.xlsx

Bigger chart

http://dl.dropbox.com/u/10334978/Mercedes%20280SL/1969%20280sl%20Cold%20Start%20CO%20%231.JPG